The right launder for every casthouse

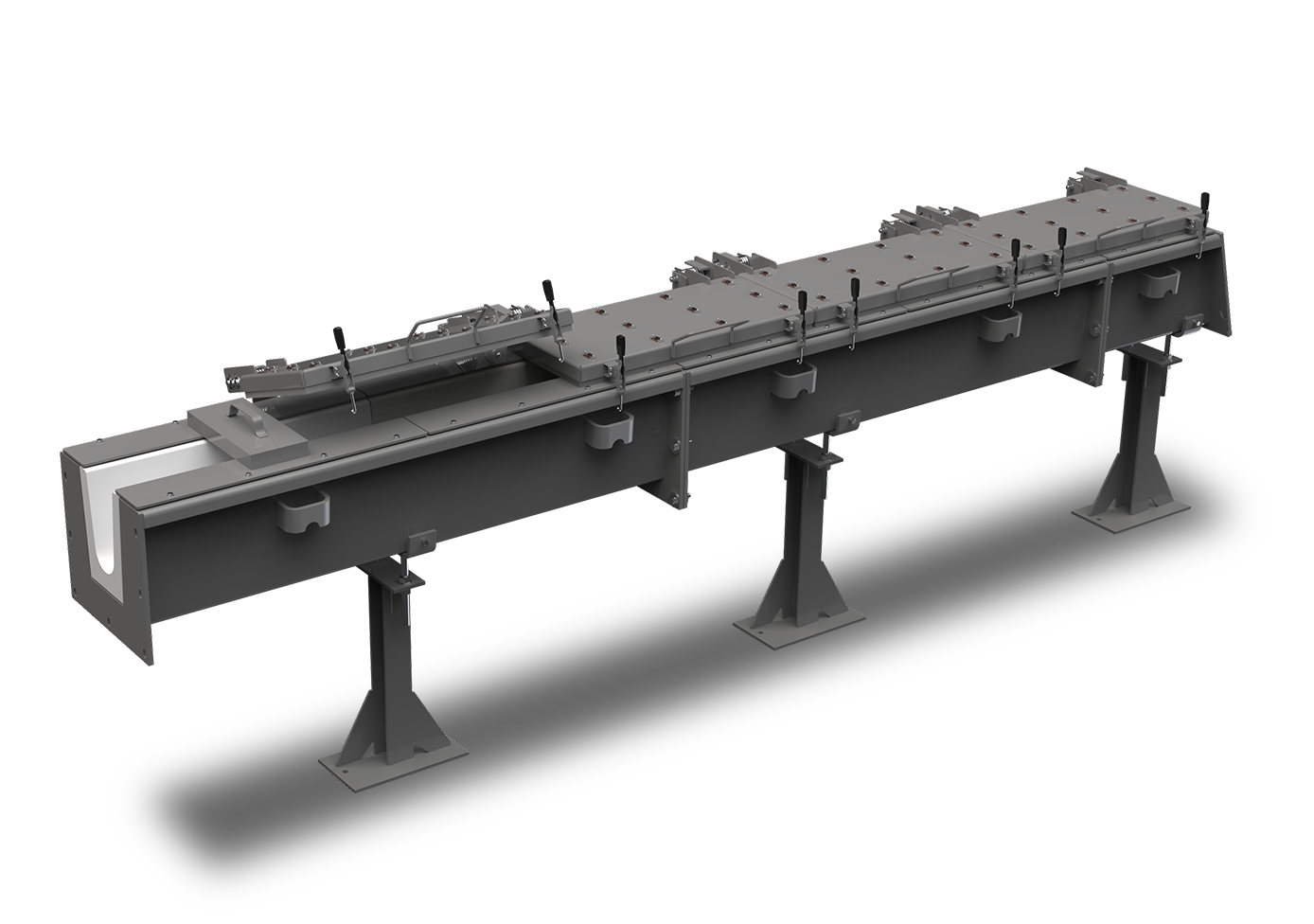

We supply launder systems for aluminium DC casting as a complete package. This includes the selection of a suitable launder cross section, the complete engineering, manufacturing, and, if desired, the installation on site. All our launder systems are optimized for a minimized heat loss, low steel housing temperature, and a calm metal flow.

Drache offers custom-tailored launder systems for every application.

Special Advantages

We will be happy to provide a free consultation on your ideas and wishes.

Feel free to contact us at any time!

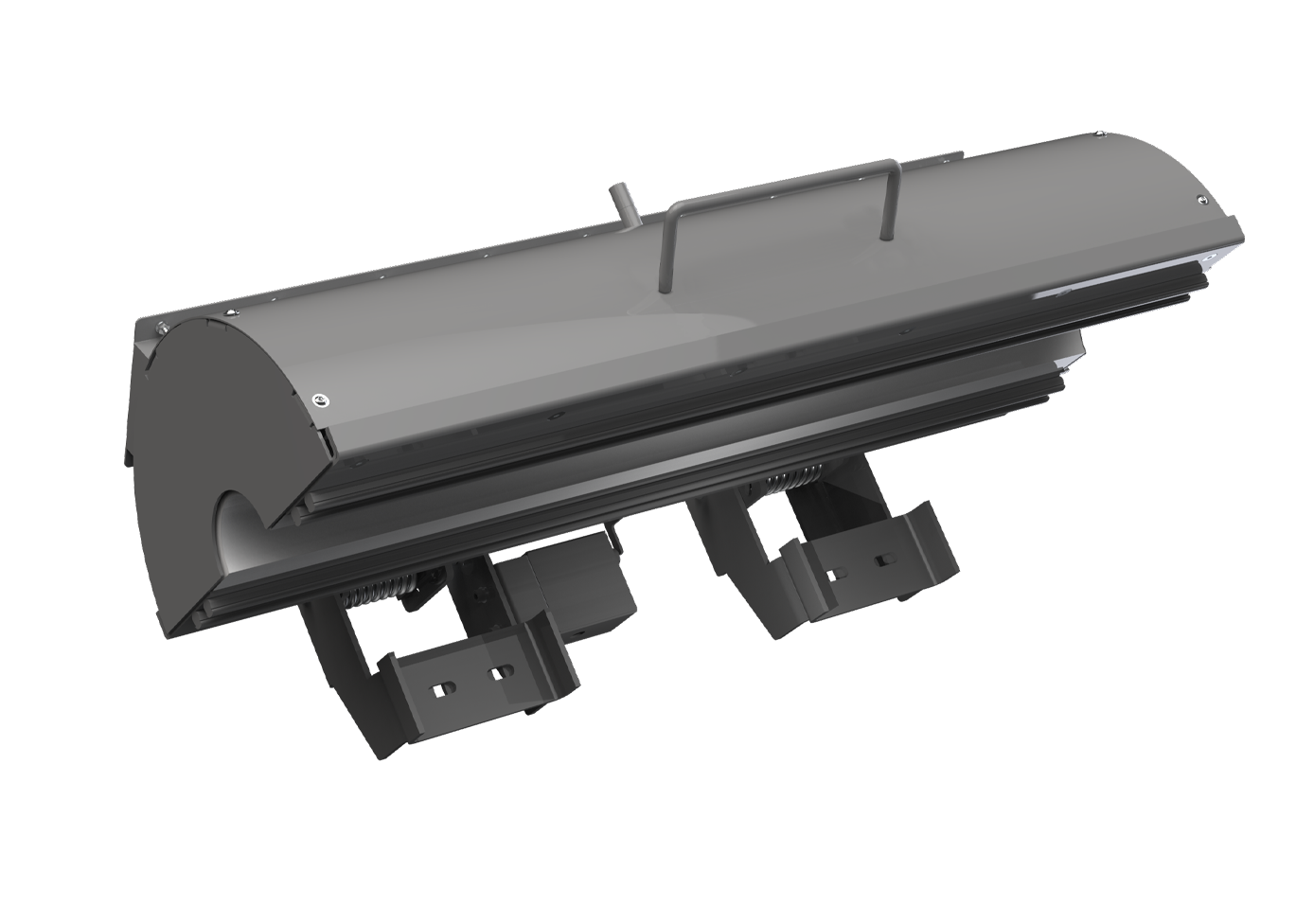

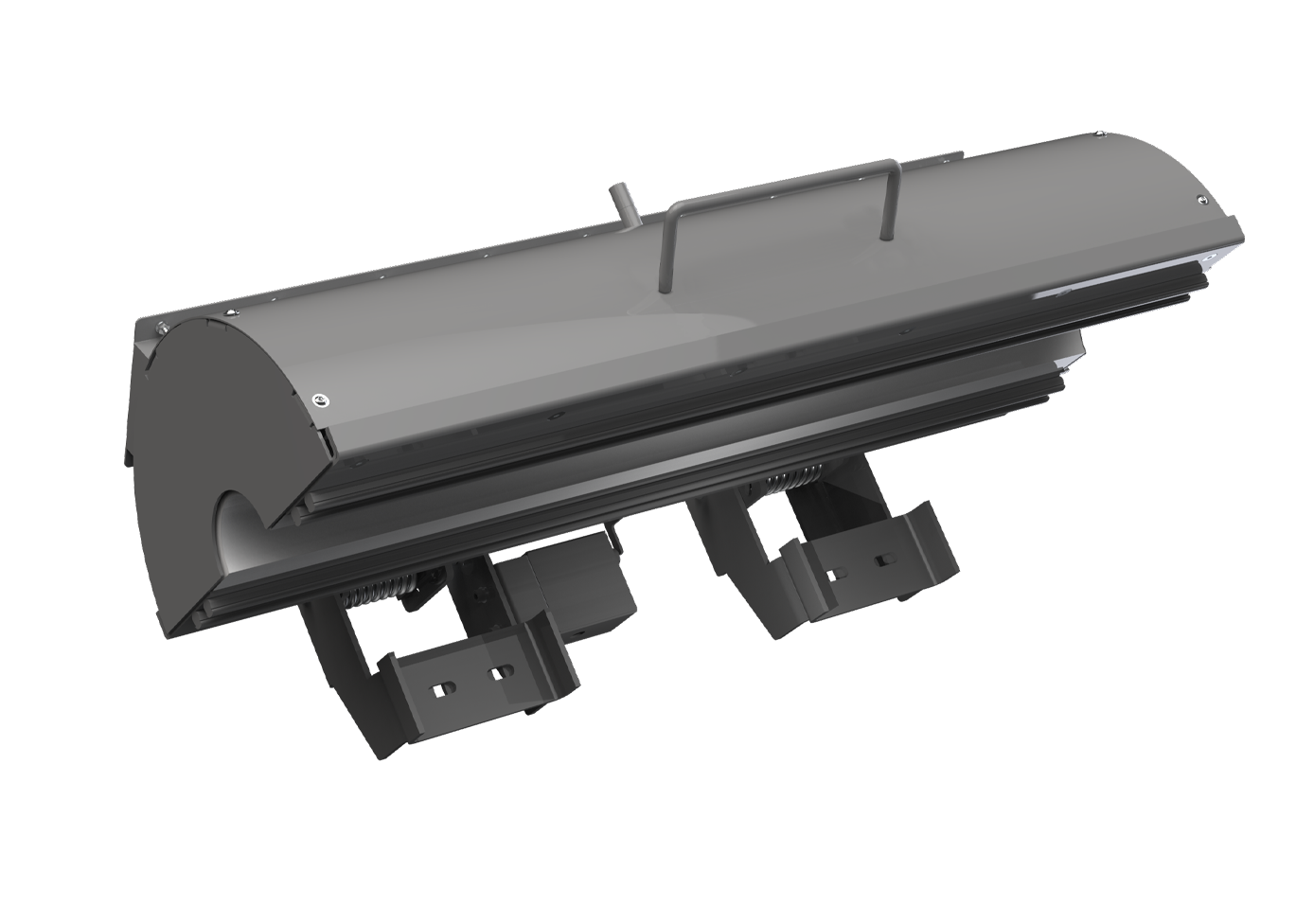

Minimized heat loss with Launder lids

To minimize the heat loss of the lauder system, lids can be installed. By reducing the heat loss due to radiation of the bath surface, the heat loss per meter of launder can be reduced significantly. Drache launder lids can optionally be equipped with a preheating system.

Drache offers launder lids for its launder systems

Special Advantages

Minimized heat loss

The launder lids can be equipped with an electrical preheating system upon request. Due to that, the heat loss can be further reduced at the beginning of the cast.

Drache offers to different systems:

A powerful, easy-to-use and robust design

Special Advantages:

Technical Data

Minimized heat loss through electrically heated lids

Special Advantages:

Technical Data

We will be happy to provide a free consultation on your ideas and wishes.

Feel free to contact us at any time!

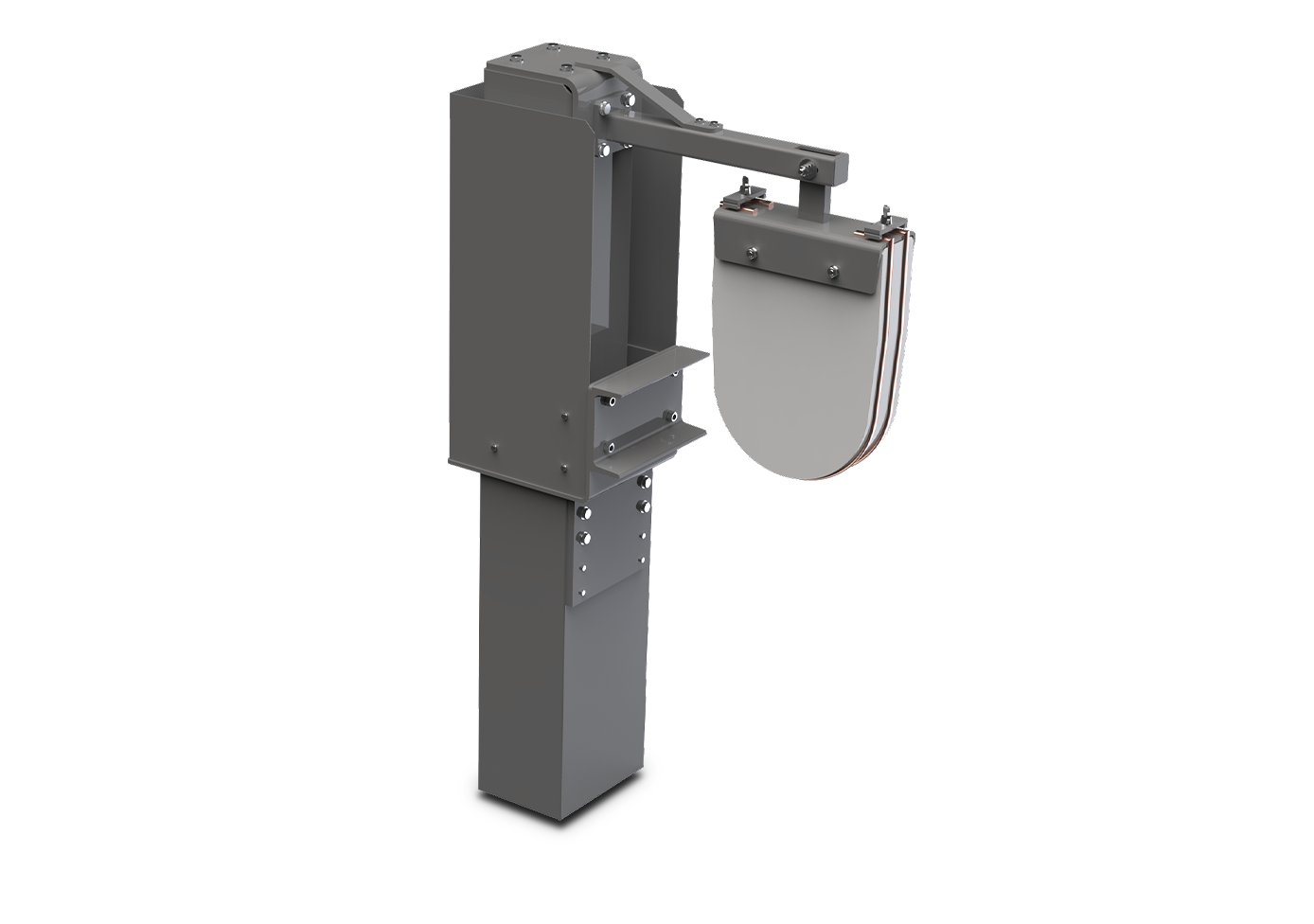

Controlled metal flow

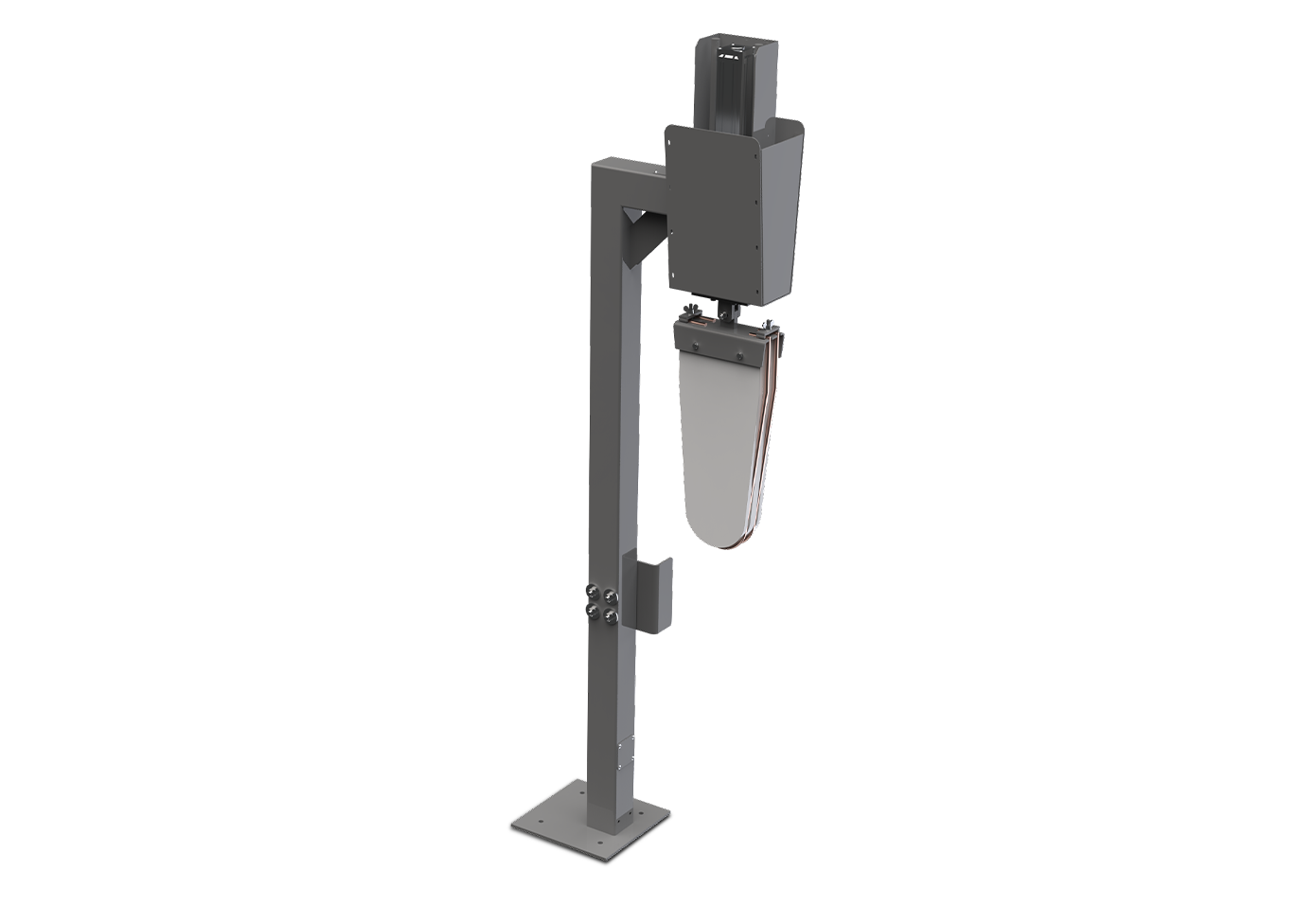

In addition to launders and launder lids, Drache also offers launder dams. The dams are available for manual operation as well as pneumatically driven. All dams consist of a calcium silicate dam board with a machined groove, a sealing rope, and a holder for the dam.

Pneumatically driven and manual dams

Special advantages

Exact flow control

Level Control Dams allow an exact control of the opening position of the dam inside the launder; thus the flow of metal can be controlled. This is possible by using an electric cylinder, which can be exactly positioned between the fully open and fully closed position. The dam plate itself is machined from calcium silicate with a double groove for the sealing rope.

Flow control by using an electric cylinder

Special advantages

We will be happy to provide a free consultation on your ideas and wishes.

Feel free to contact us at any time!

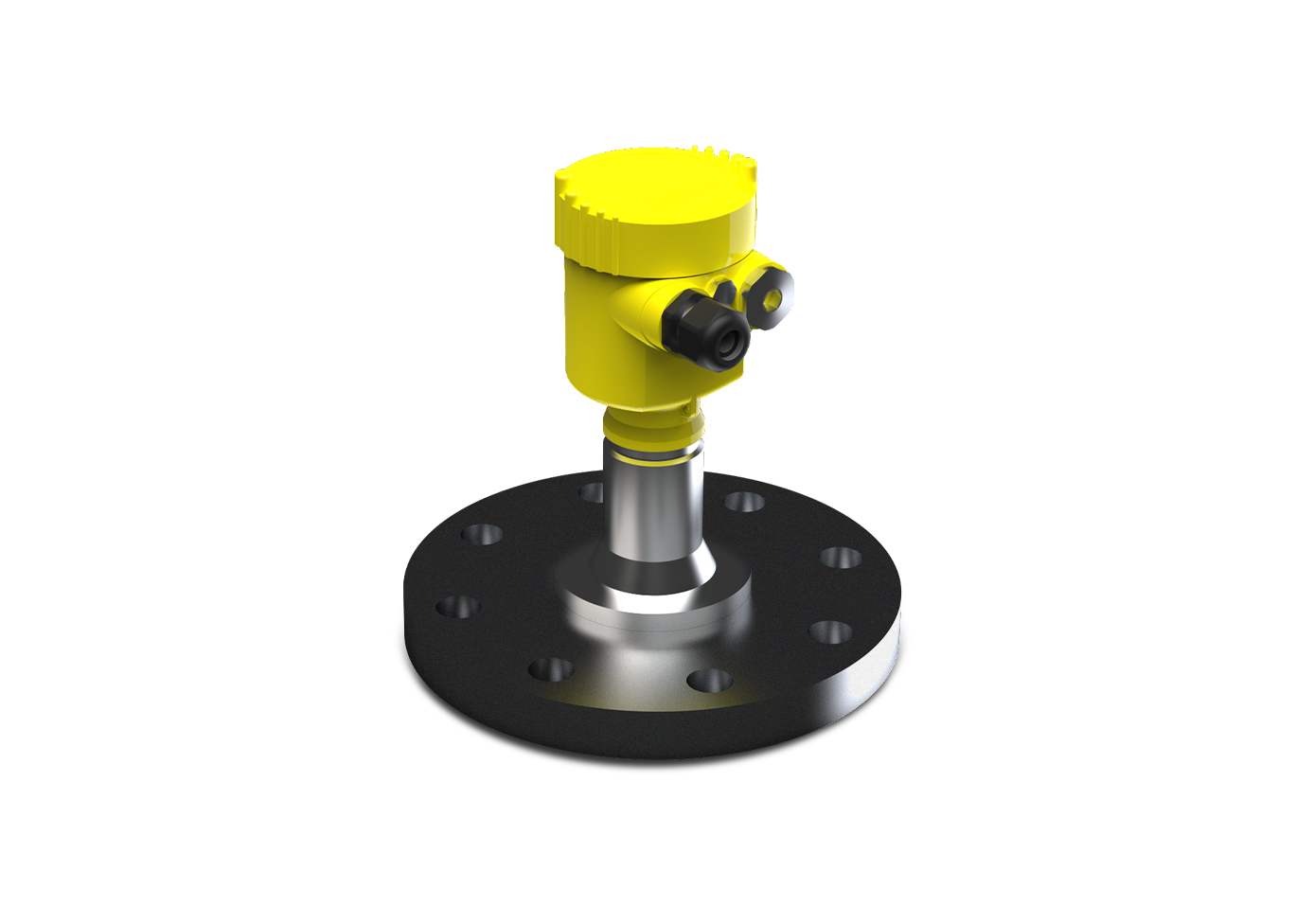

Measurement of the metal level inside the launder

The metal level of the aluminium inside the launder can be monitored by the help of radar sensors. These are placed on a holder above the launder, allowing an accurate metal level detection.

Fast and accurate metal level measurement

Special advantages

Contact

If you need help or have a question regarding filters, system construction, another product or even a custom solution, please fill out the contact form below.

How can we help you? *

Since 1984, Drache Umwelttechnik GmbH is supplying innovative and sustainable products and equipment in casthouse technology. We focus on the highest quality standards and new technologies.

Drache Umwelttechnik GmbH

Werner-von-Siemens-Str. 24-26

D-65582 Diez

Deutschland

+49 64 32 – 60 70

mail@drache-gmbh.de

© Drache Umwelttechnik GmbH